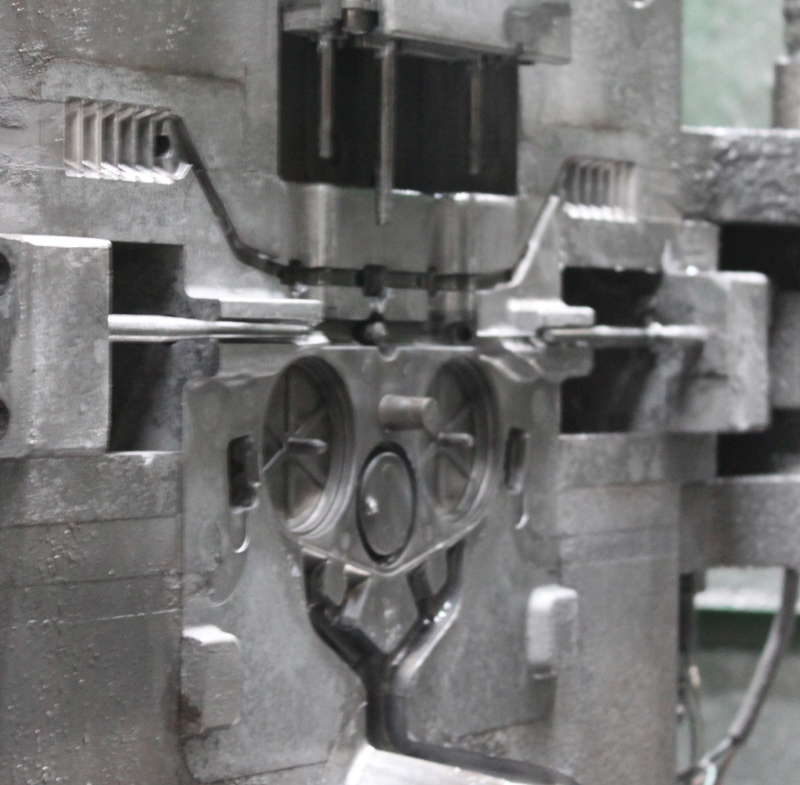

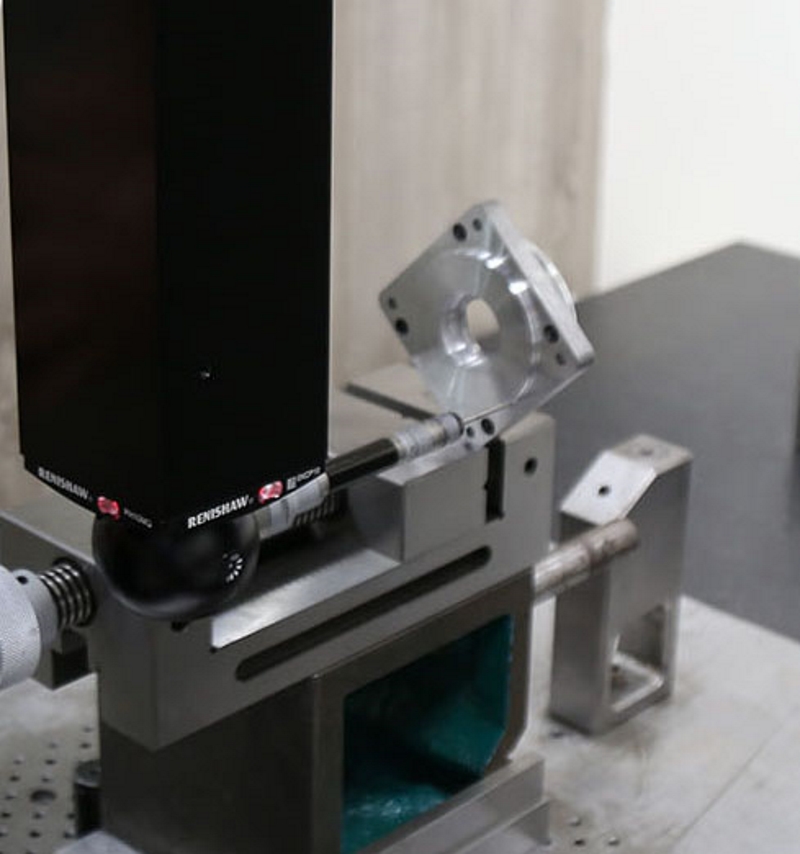

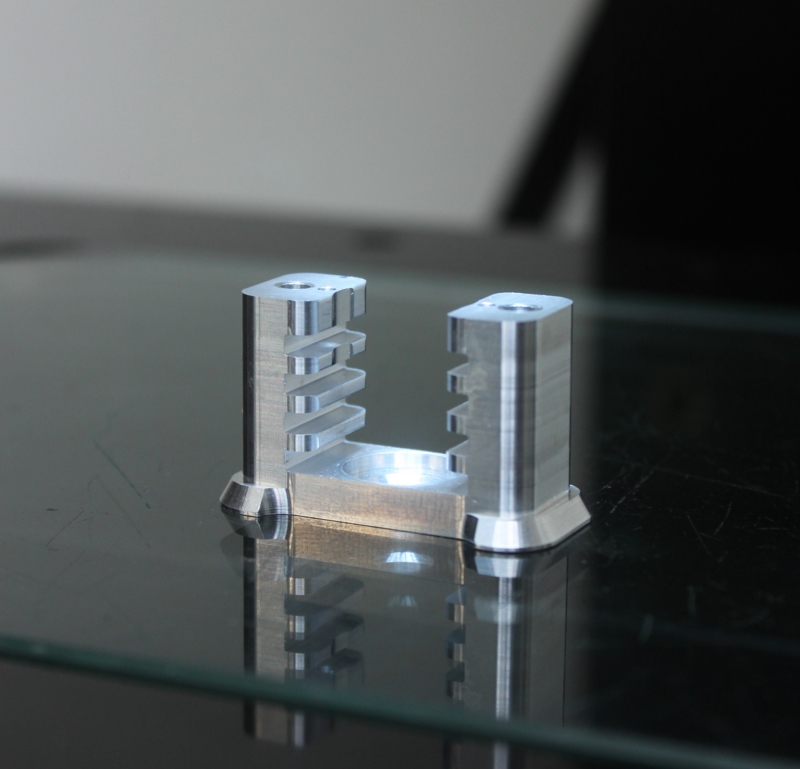

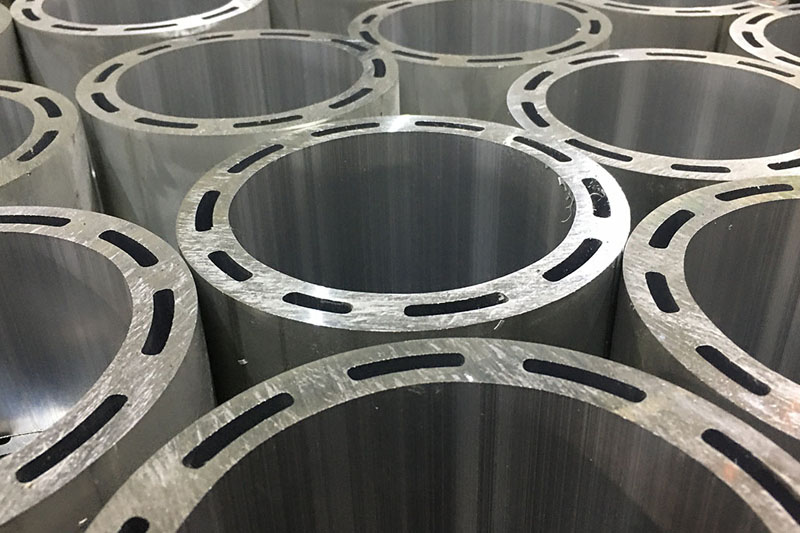

precision die-casting, grinding, CNC parts processing, mold designs for die-casting, die-casting molding, vacuum die-casting

Located in Taiwan, Wangpai Precision Die-casting has been dedicating on developing die-casting molds and zinc aluminum die-casting processing, one-stop local CNC die-casting parts processing and manufacture of MIT quality standard.

Established in 1987, Wang Pai is professional in die casting precise aluminum alloy and zinc alloy products. Leading by President Kao and Vice President Chen, Wangpai has emerged from its small beginnings of being a simple OEM maker to what it is now--A Global Company with Integrity. The journey getting to where we are is marked by persistence, diligence, responsibility, and constant maintenance of standards and quality.

Since our company was founded in 1960, our economic growth and increasing client base have been built on the sincere appreciation of concept. By following strictly our business principle “contribute to the creation of a safe society and the development of mankind by producing excellent products for our clients”, we have strived to improve by constant effort and research.

Globalization is becoming more and more obvious. As a leading company, we have to work towards the improvement of die casting technology, molding, precision processing, assembly, and total management techniques. "Best" will be the best gratitude to the customer.

MAIN SERVICE FEATURE:

From mold making, mold design, through precision die-casting processing, Expert of die-casting (aluminum die-casting, zinc die-casting, vacuum die-casting, aluminum alloy die-casting, zinc alloy die-casting, die-casting molds) processing. We are professional in making MIT quality die-casting products, and with the support of the deep ploughing experience in the field for over 40 years in Taiwan, dedicating on R&D most advanced technique in die-casting, and on offering complete control of product quality for fashion pursuing of our clients.

Video of die-casting plant:

A quick look of die-casting process and departments of Wangpai

The key development history and milestones

As a professional die-casting company, we ensure parts from here meet applications in various industries.

- 1987 Wangpai founded with capital NT$150,000.

- 1992 Moved to Lungmi Road, section 2, Bali to increase production capacity

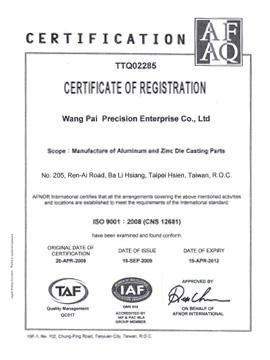

- 1998 imported into ISO-9001

- 1999 Certified ISO-9001 on March 24.

- 2002 ISO-9001 renewed to 2000 version

- 2002 Basing on management philosophy of quality first, shipment on time, service perfect, we made the crucial decision of plant enlargement in 2004

- 2003 trial orders placed from Europe, and was praised, customers sent examiners to visit upon knowing plant enlargement of this company.

- 2004 Assisting European clients to improve strength long-lasing problems in their parts in March, started making them to be our important customers.

- 2004 trial orders placed from Europe, and was praised, customers sent examiners to visit upon knowing plant enlargement of this company.

- 2006 Grand opening increasing CNC three dimensional.

- 2006 CNC processing department established in August.

- 2006 Assisting developing 1.8 action disc and digital photo storage box and won silver prize and excellence prize of Taiwan Excellent Awards next year.

- 2008 Purchased 5 sets of 4 –axis processing machining centers in June.

- 2008 Undertaking audio-visual peripheral equipment of ASUS notebooks

- 2009 Assisting Geo Vision develop monitor system and set up assembly department.

- 2010 Enlarged and established assembly plant.

- 2011 Undertaking parts of POS computer system for Flytech Technology Company

- 2012 Undertaking stylus for ASUS pad-phones

- 2012 Equipped with 20 sets in CNC processing department

- 2014 formerly engaged in R&D of motors with GOGORO, and purchased one set each of cold type die-casting machine 400T and 800T.