Zinc Die Casting Alloys Process and Mold design

Why choose Zinc Die Casting Alloys Alloys?

The high strength and hardness of zinc alloy makes itself the optimal substitute for machined, casting, die-punched and assembly components. Compared to zinc extruded alloy, zinc alloy has excellent shock-absorption capability and vibration absorption capability. Zinc alloy casting molds feature longer longevity and cheaper molding cost than those in aluminum alloy.

Zinc Alloy Characteristics

| ◆ High strength and hardness | ◆ High precision size and stability | ||||

| ◆ High quality fixing feature | ◆ Excellent electricity conduction | ||||

| ◆ Remarkable thin-wall filling capability | ◆ Distinguishing anti-corrosion | ||||

| ◆ High heat conduction | ◆ Good room-temperature forming and easy jointing | ||||

| ◆ Adequate recyclable utility | ◆ Superior electroplating characteristics |

Table of zinc alloy ingredient and coefficient in zinc alloy die-casting:

Importance of coefficient and ingredient related to die-casting alloy products, as each metallic material has certain advantage and ingredient representative.

| Material | Al | Mg | Cu | Fe | Pb | Cd | Sn | Zn |

|---|---|---|---|---|---|---|---|---|

| Alloy 3 | 3.5~4.3 | 0.02~0.05 | 0.25max | 0.1 | 0.003 | 0.004 | 0.005 | Bal. |

| Alloy 7 | 3.5~4.3 | 0.005~0.02 | 0.25max | 0.075 | 0.001 | 0.002 | 0.003 | Bal. |

| Alloy 9 | 3.5~4.3 | 0.03~0.05 | 0.75~1.2 | 0.1 | 0.003 | 0.004 | 0.005 | Bal. |

| Alloy 2 | 3.5~4.3 | 0.02~0.05 | 2.5~3.0 | 0.1 | 0.003 | 0.004 | 0.005 | Bal. |

| ZA-8 | 8.0~8.8 | 0.015~0.03 | 0.9~1.3 | 0.075 | 0.003 | 0.006 | 0.006 | Bal. |

| A-12 | 10.5~11.5 | 0.015~0.03 | 0.5~1.2 | 0.075 | 0.003 | 0.006 | 0.006 | Bal. |

| ZA-27 | 25.0~28.0 | 0.01~0.02 | 2.0~2.5 | 0.075 | 0.003 | 0.006 | 0.006 | Bal. |

With the best equipment, we offer you the best quality products.

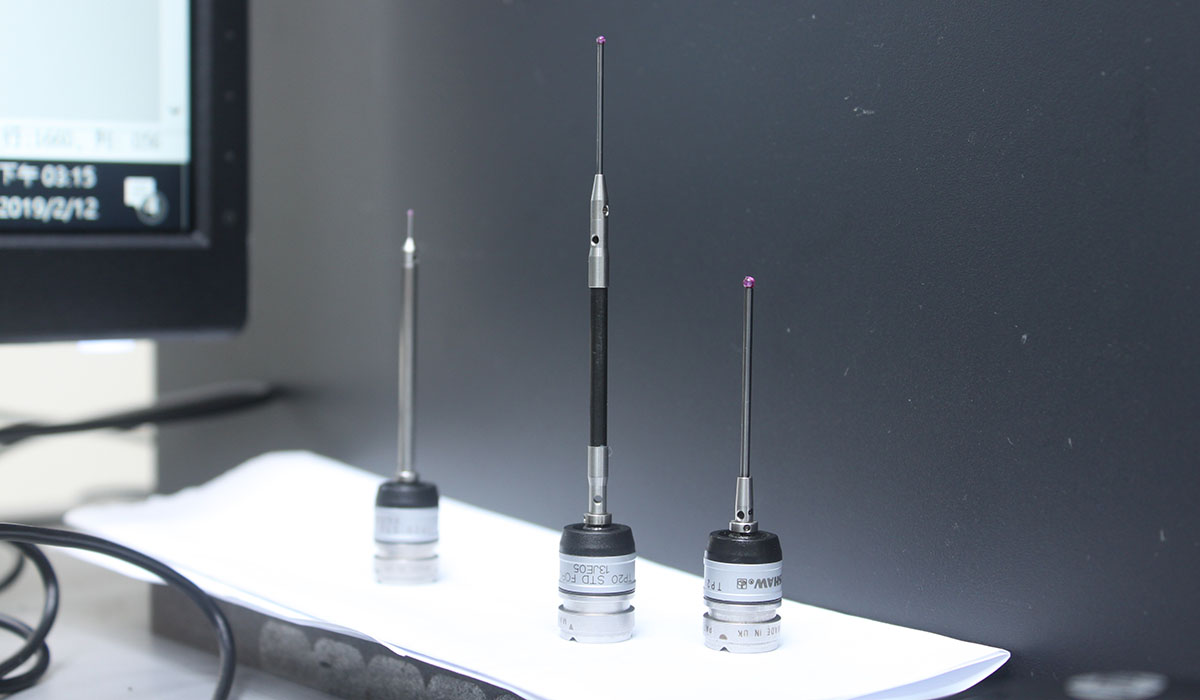

5 sets of 50-ton zinc die-casting machines ; 1 set of 130-ton zinc die-casting machine; 2 sets of vacuum die-casting machines; three-dimensional measuring instrument; 10 sets of CNC processing machines; 10 sets of hydraulic punches; 2 sets of traditional lathes; 2 sets of horizontal milling machines; 5 sets of drillers; 5 sets of tapping machine; I set of sandblasting equipment, etc.

- Machines coming with good performance able to make precision parts of complicate shapes, thin walls, and smooth appearance.

- Surface treatments accessible: plating, spraying, and spray painting.

- No magnet iron attracting, no corrosion to die-cast shapes, no mucosa during melting and die-casting.

- Coming with great mechanical properties at room temperature equipped with abrasion resistance.

- Low melting point, melted at 385℃, easy to be shape die-cast.

Do's and don't's during use::

(1):Bad in corrosion resistance when the alloy material contains impurity elements of lead, cadmium, tin that exceed the standard, that result in the casting deformation out of ageing, and which appears volume expansion, apparent decrease in mechanical behavior, especially in plasticity, and eventually will result in ruptures. As lead, tin, and cadmium very low in solubility in alloy, they gather in grain boundary as cathode, while the allitic limit solid solution acts as anode. When in the condition of steam (electrolyte), it contributes intergranular corrosion and thus age casting.

(2) Aging effect : Zinc alloy mainly contains zinc-rich solid solution of al and cu. The solubility decreases following decrease in temperature. As solidification rate of casting is very fast, when it reaches room temperature, solubility of solid solution becomes fully saturated. After a certain time, the over-saturation will gradually relieve, making the changes in shapes and sizes of the casting.

(3) As temperature affects zinc alloy casting, high or low temperature (below 0℃) is not suggested. Under room temperature, zinc alloy has better mechanical behavior. The tensile strength under high temperature, and the impact performance under low temperature apparently decrease.

Exhibition of zinc die-casting and zinc alloy die-casting products

Development and manufacture of zinc alloy die-casting products for varied industries are available, as we are equipped with complete zinc alloy die-casting machines and post processing services such as CNC, sandblasting, electroplating coating, powder coating, three dimensional detection instrument, X-ray structure irradiation machine, to follow you as per your requirements.